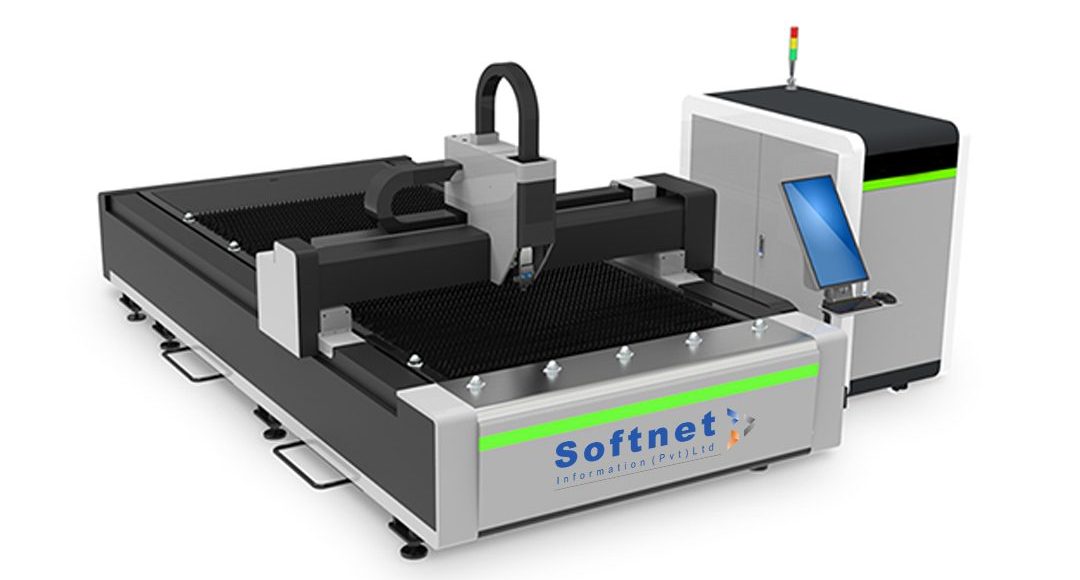

Industrial Fiber Laser Cutting Machine Training

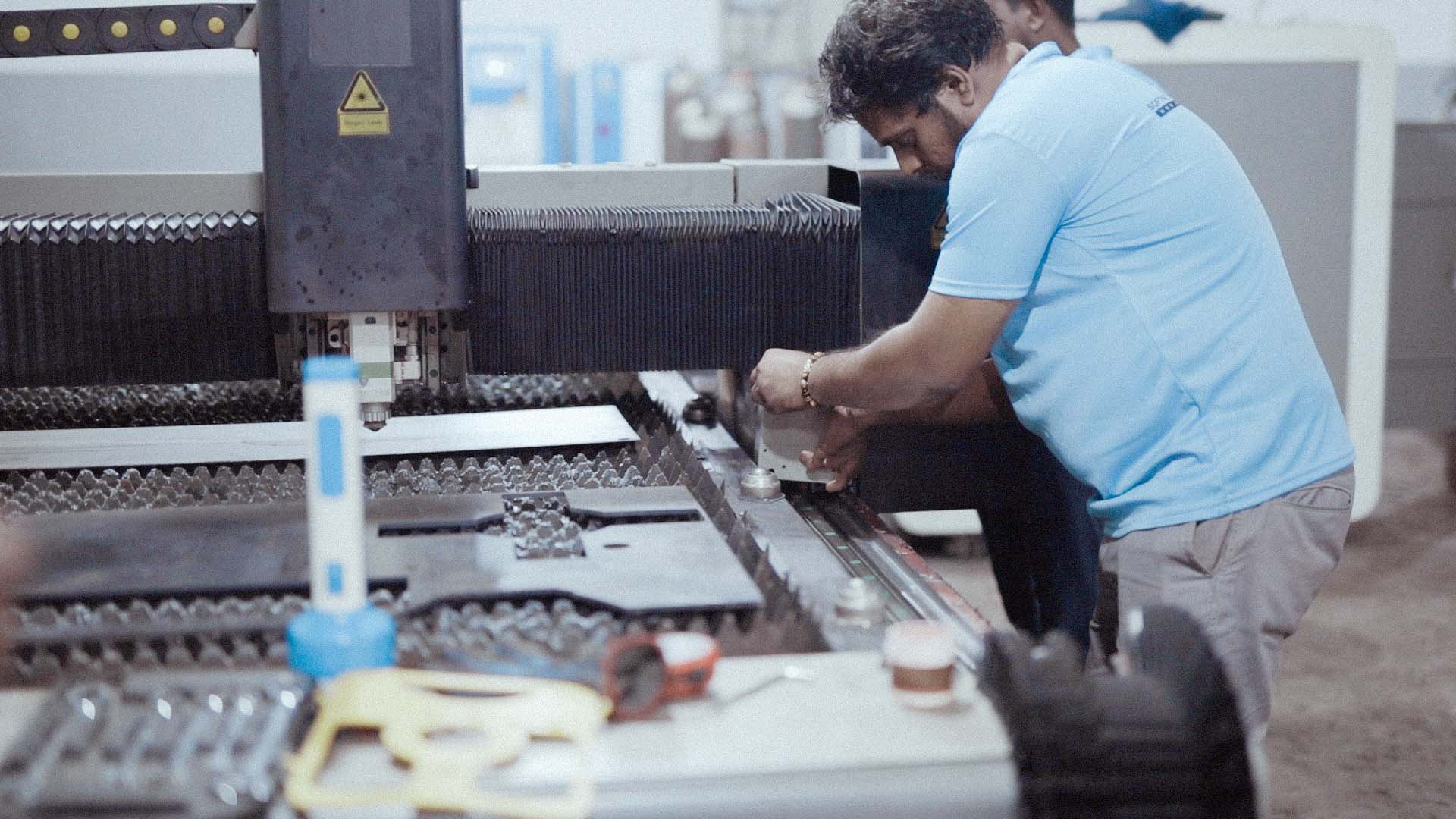

Softnet Fiber laser metal cutting machines have revolutionized precision engineering and material processing in modern industrial manufacturing. These advanced machines offer speed, accuracy, and versatility in metal cutting applications. As demand for these machines increases, comprehensive industrial training programs are crucial to fully utilize their potential. This essay explores the intricacies of industrial training for these machines, focusing on technology understanding, operational skills, safety protocols, and the broader implications for the manufacturing sector.

Understanding Fiber Laser Metal Cutting Technology:-

Fiber laser metal cutting machines use high-energy laser beams to interact with metal surfaces, providing a non-contact, thermal-based cutting process. The fiber laser resonator generates an intense beam directed through a fiber optic cable to the cutting head, enabling high-speed cutting across various metal types and thicknesses. This advanced technology offers precise and clean cuts.

Operational Expertise:-

Softnet Industrial training for fiber laser metal cutting machines focuses on developing operational expertise, including machine setup, calibration, and cutting parameters. Trainees must understand laser power, cutting speed, and focal length’s impact on the cutting process. Practical hands-on training sessions familiarize trainees with the machine interface and control software.

Safety Protocols:-

The text emphasizes the importance of training programs for operators and technicians dealing with powerful fiber lasers for metal cutting, emphasizing the need for protective equipment, safe working distances, and proper ventilation systems to ensure a secure working environment.

Material Specifics and Adaptability:-

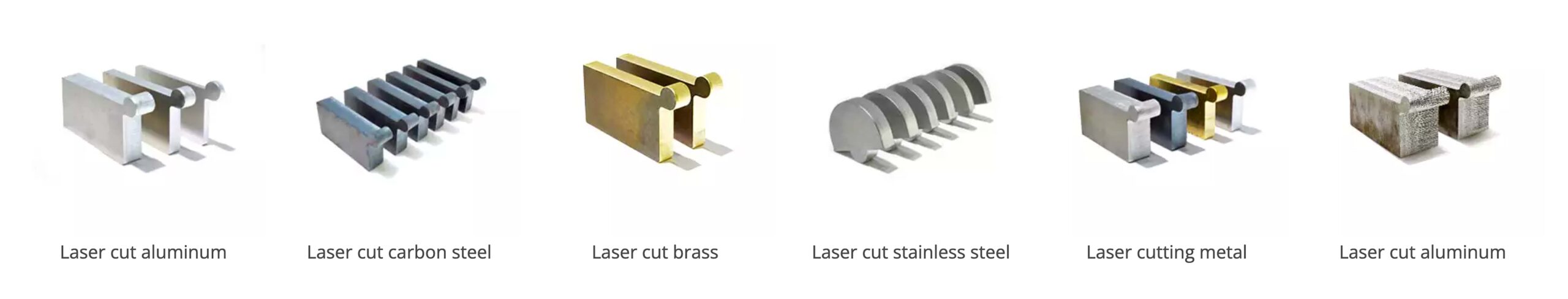

Softnet Fiber laser metal cutting machines are versatile and can cut various metals like steel, Aluminum, and copper. Industrial training programs should understand each material’s properties to optimize cutting parameters, ensuring optimal results across various manufacturing applications and achieving material-specific requirements.

Precision Programming and Software Proficiency:-

Fiber laser metal cutting’s effectiveness relies on precision programming and software proficiency. Softnet Training programs should cover CAD software for creating cutting patterns and machine-readable code, as well as machine control software for executing intricate cuts, adjusting parameters, and optimizing production efficiency.

Maintenance and Troubleshooting Skills:-

Trainees should acquire skills in machine maintenance and troubleshooting to maintain productivity. This includes routine tasks like cleaning optics and aligning the laser beam. Comprehensive training can help operators identify and resolve common issues, reducing downtime.

Quality Assurance and Inspection Techniques:-

High-quality cuts are crucial in the manufacturing sector, and training programs should include quality assurance modules. Operators should learn to inspect finished products, measure dimensional accuracy, and implement corrective measures, enhancing the overall value of fiber laser metal cutting machines.

————————————–

Softnet Fiber laser metal cutting machines are a significant advancement in industrial metal processing, but their full potential requires a skilled workforce. Industrial training programs should cover understanding of fiber laser technology, operational expertise, safety protocols, material knowledge, programming and software proficiency, maintenance, troubleshooting, and quality assurance. Investing in skilled professionals can unlock the true potential of these machines, driving innovation and efficiency in the manufacturing industry.

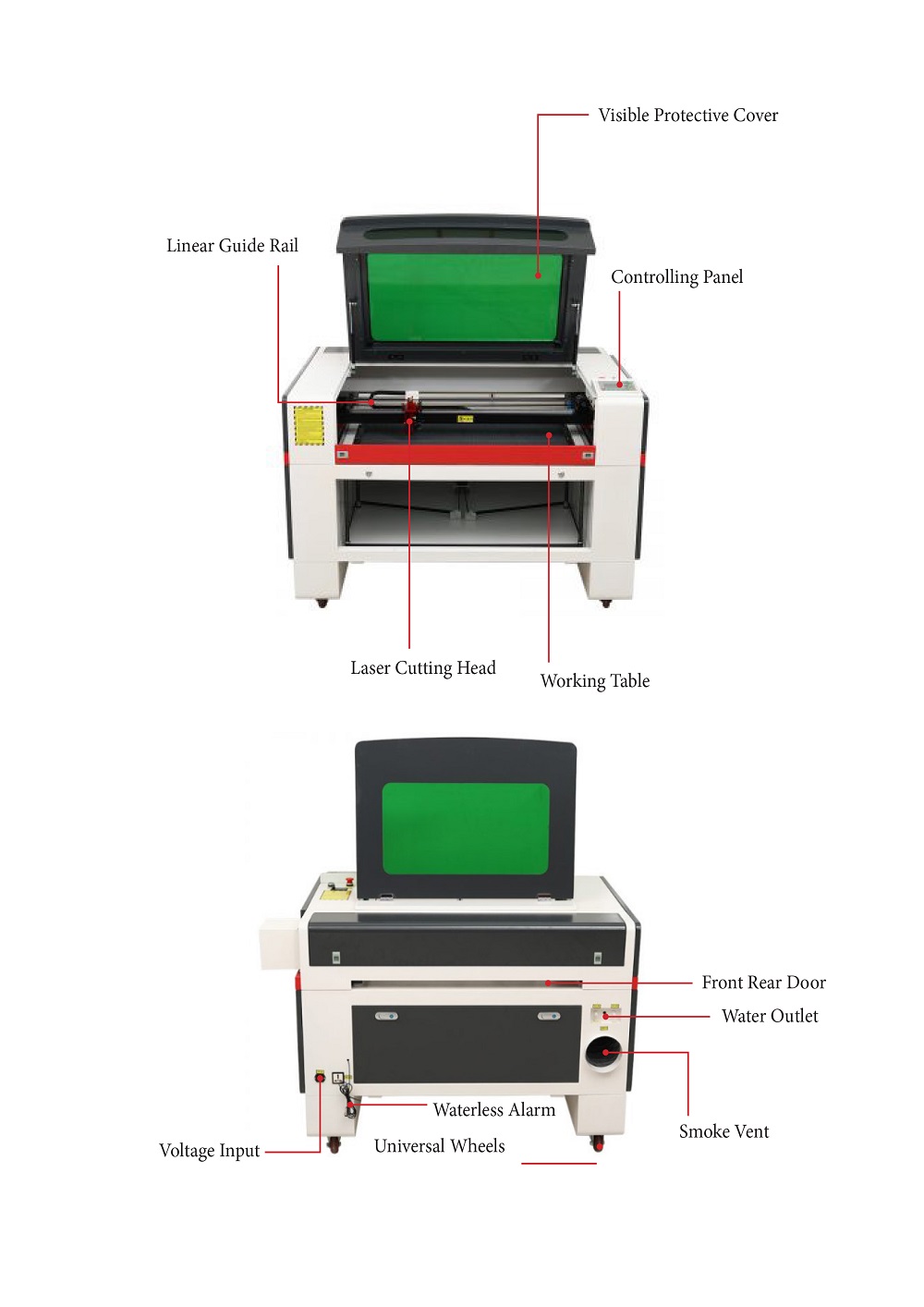

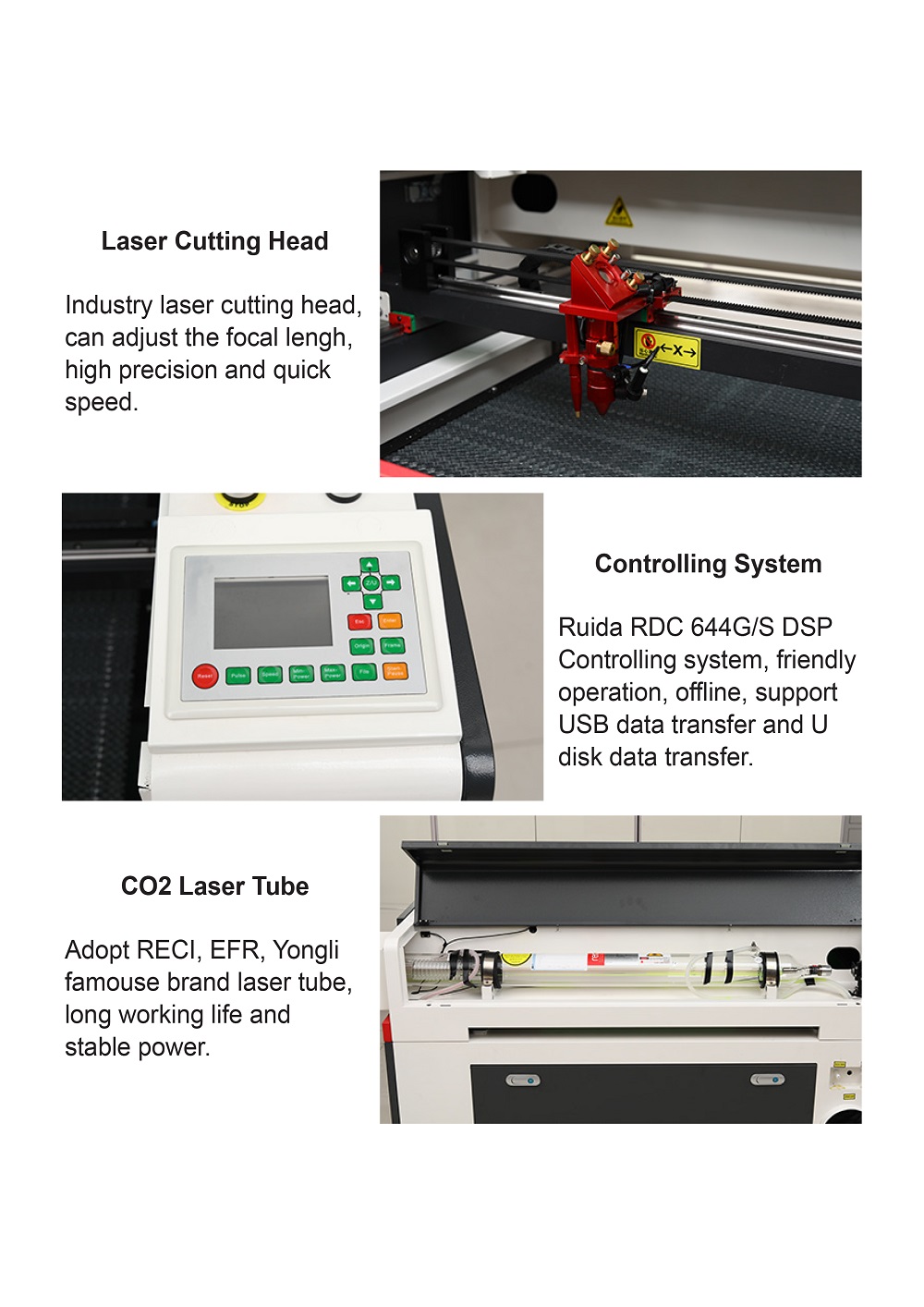

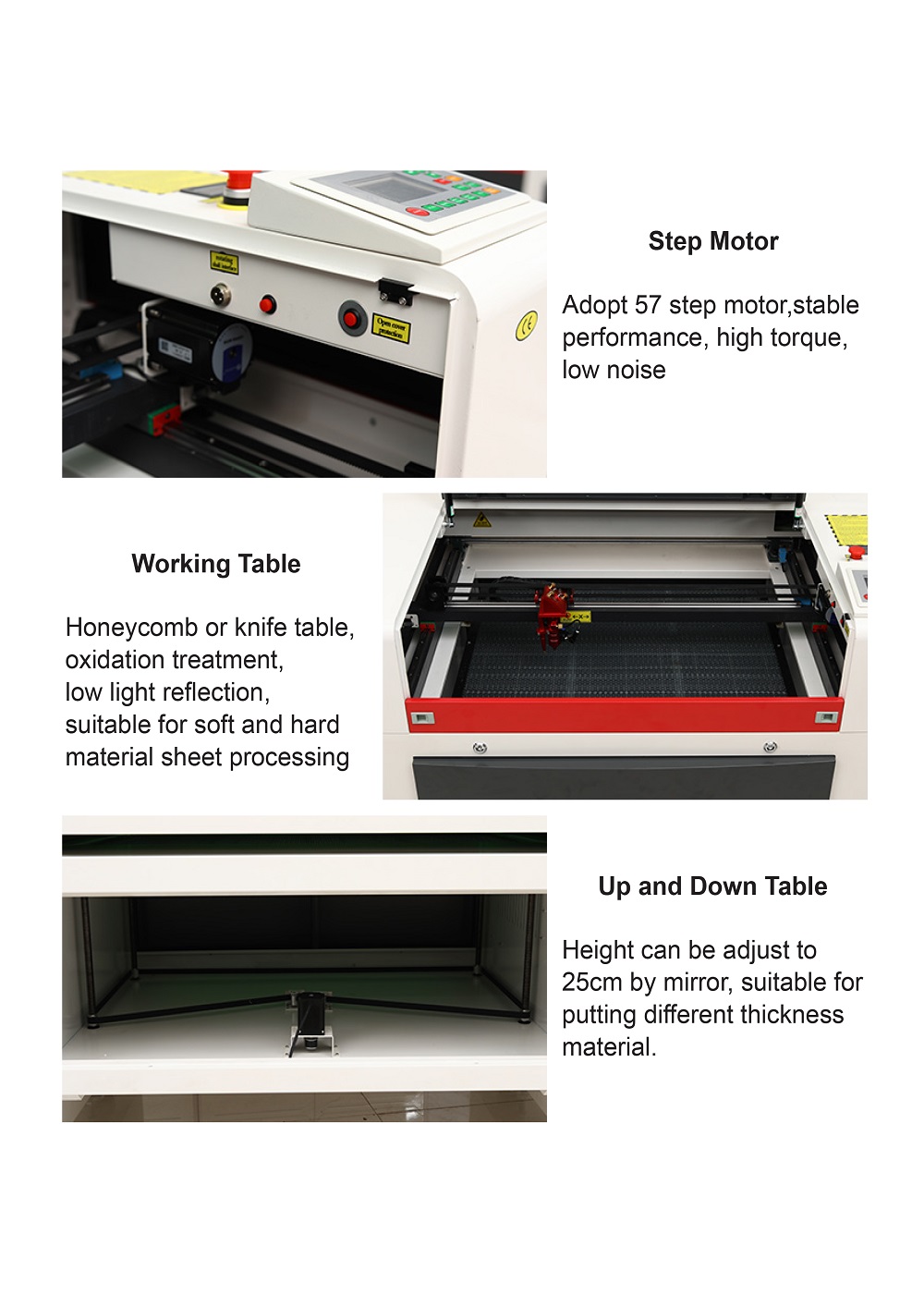

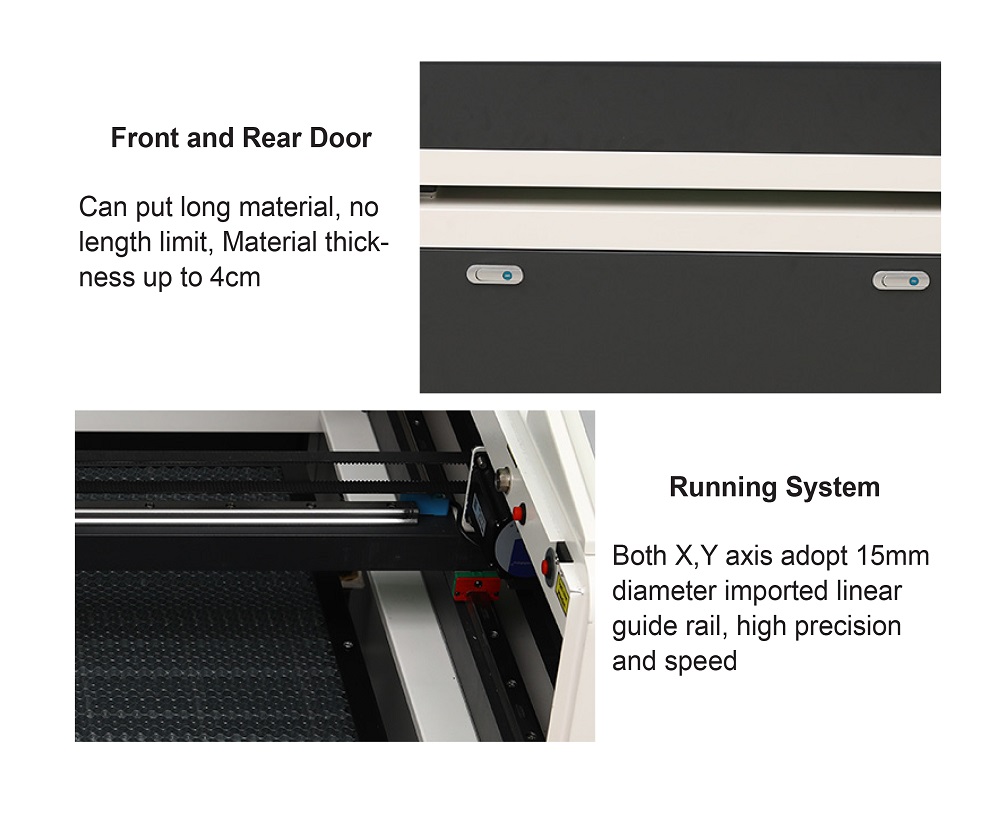

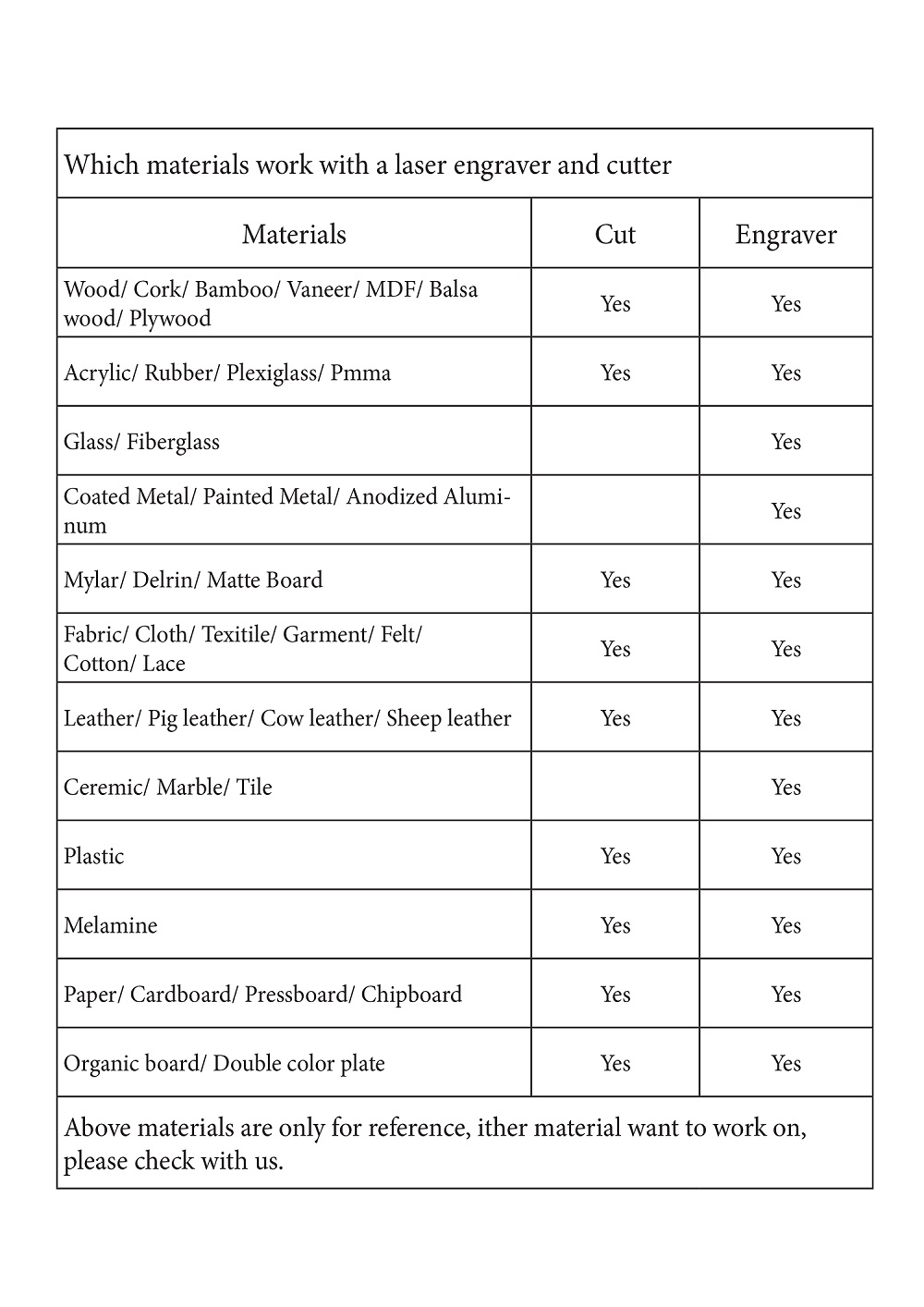

CO2 Laser Engraving and Cutting Machine- SN 6090

High-Quality Laser Engraving and Cutting machine

Vinyl Plotter C24 (720mm)

24“Vinyl Cutting Plotter Support Auto contour cutting. It can cutting a variety of special materials, such as soft fabric, transparent materials, reflective materials, black materials, white materials, color materials.

Features of C24.

- Large touch screen menu High sensitivity.

- Simple use and straightforward operation.

- Multi-languages

- User-friendly Touchscreen / Keypad for easy handling

- Powerful function like: Can array-freely set to cut many lines and many columns, and free set distance between each copy.

- Multi-interface

- USB cable (real USB, no need to install driver)

- U disk (support both normal cutting and contour cutting)

- Wifi (optional)

- Compatible with Windows & Mac

Camera for auto contour Cutting.

This Plotter patent feature-build in real camera for auto print and cut.

High-accuracy, fast speed and capable for any color materials and marks, such as,

High reflective materials – Can cut 3M Diamond reflective film (Huge force :max 2000g)

Various color materials

Transparent materials

Any color marks

-

Fully Adjustable Pinch Feed Assembly.

The pinch wheels can be individually arranged in a more convenient location, without cutting mat, it can cut materials ranging from 20mm (0.8″) to 260mm (10″), up to 24″ on the larger model

-

Metal body

This plotter model C vinyl cutter has a cute body but has an industrial professional design with a metal body. Stronger, stable, and higher accuracy. It has a max 750g cutting force, easily cut many materials including vinyl, cardstock, HTV, fabric, EVA foam, and more.

-

Multi-Colored LED Lighting

Users can freely change LED light color and it is cool when use a cutter in the evening.

-

Laser Engraving(optional)

The vinyl cutter has an optional laser part. Easily hang it on carriage cover, user can engrave on wood, paper ect.

-

Engraving tool(Optional)

Hard Diamond blade. User can easily engrave on metal, acrylic etc

What type of camera that used for C24 plotters?

Which is Andor’s iKon-L High Dynamic Range CCD camera that offers outstanding resolution, field of view, sensitivity, and dynamic range performance. It boasts a proprietary large area 5-stage TE cooler enabling cooling of this large area sensor down to an unprecedented -100°C without the aggravation of liquid nitrogen. NEW ‘Dual AR Extended Range’ sensor option offers the broadest QE coverage, from UV to NIR.

• TE cooling to -100°C

• Large area 2048 x 2048 sensor

• 4-speed readout up to 5 MHz

• Low read noise

Sublimation 3D Vacuum Heat press ST-3042

What is Sublimation 3D Vacuum Heat press ST-3042 machine?

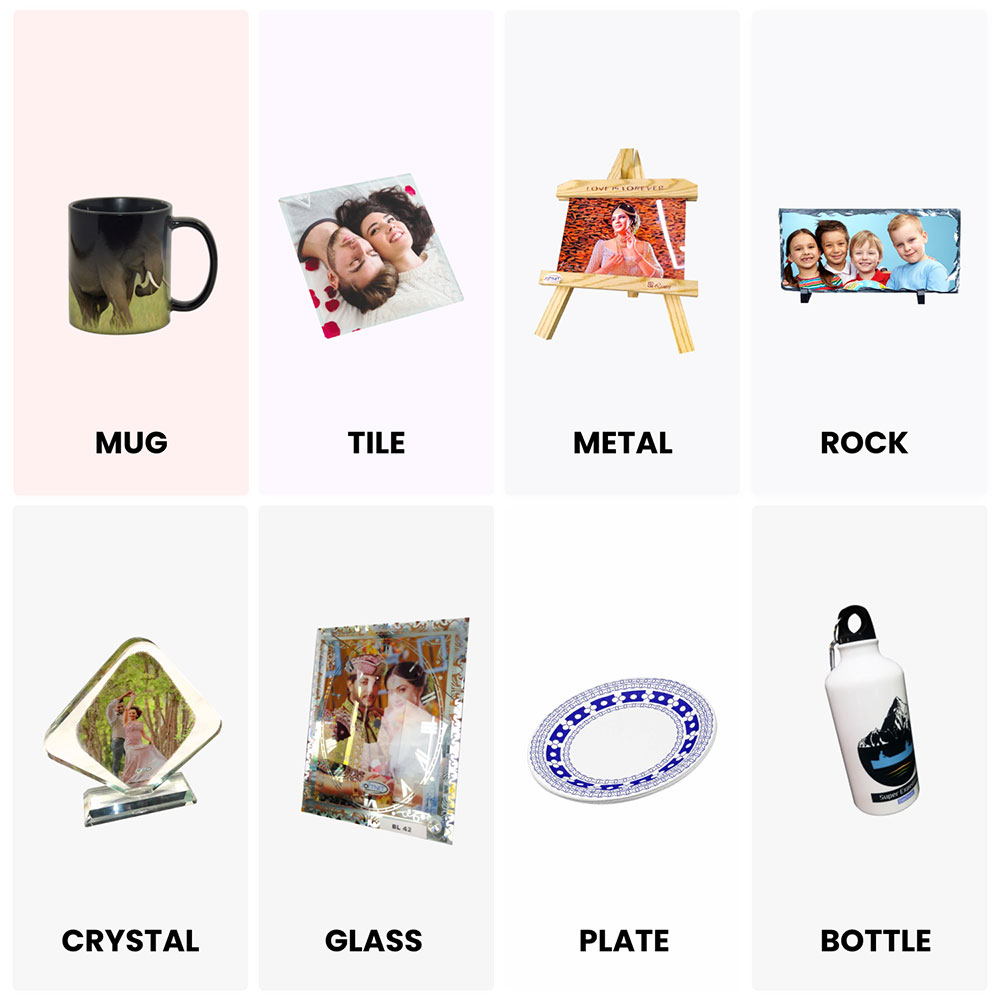

This is a machine designed to print a pattern or graphic using vacuumed and heat on a verity material such as a mobile cover, mugs, Metal sheets, Rocks and Tiles. It is the application of heat and pressure for a predetermined period of time. The pattern is printed using sublimation ink on sublimation paper that allows the pattern to be changed. Using this technology, you can get very effective designs and great outputs.

Specification of this machine

| Product Code | ST-3042 |

| Type | Vacuum Heat Press Machine |

| Weight | 26kg |

| Voltage | 220V |

| Machine Power | 2900W |

| Vacuum flow | 33L/min |

| Max Vacuum | -640mmHg |

| Usage | Phone case, Mug, Glass Crystal, Rock, Metal, Plate |

| Warranty | 1 Year |

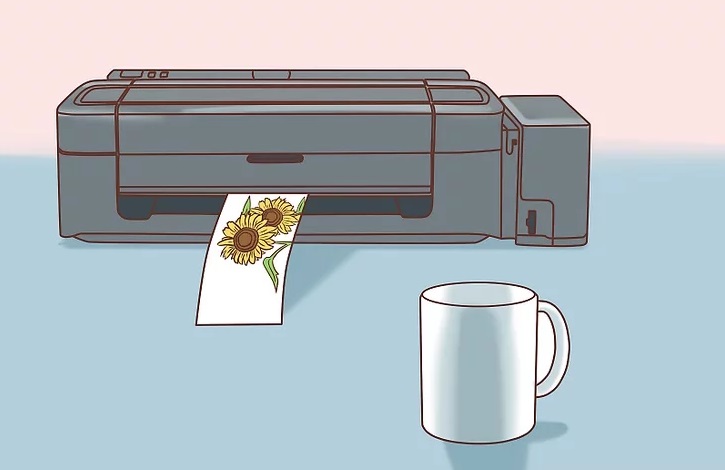

What supplies are required?

To print the material, we need an Inkjet printer, Sublimation Paper, Sublimation material or the necessary material, Sublimation Ink set, heat tape, heat glows and the 3D machine.

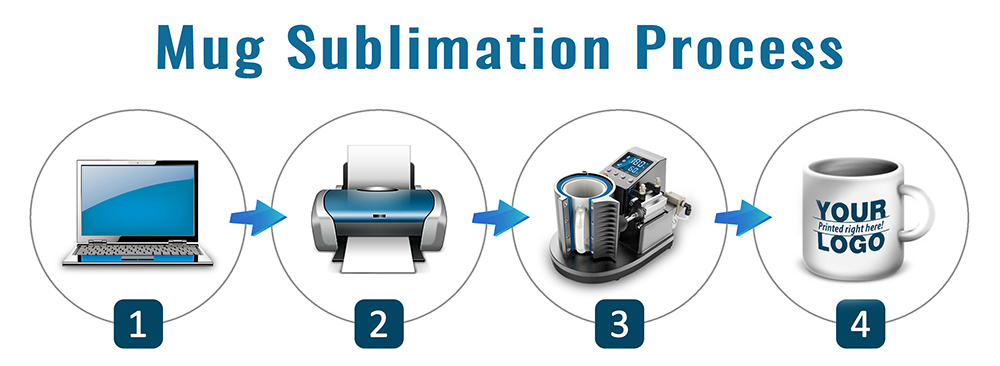

Step by step guide to print the material:

- Design the artwork on your PC.

- Print out the image or text to the sublimation paper.

- Cut out the specific image.

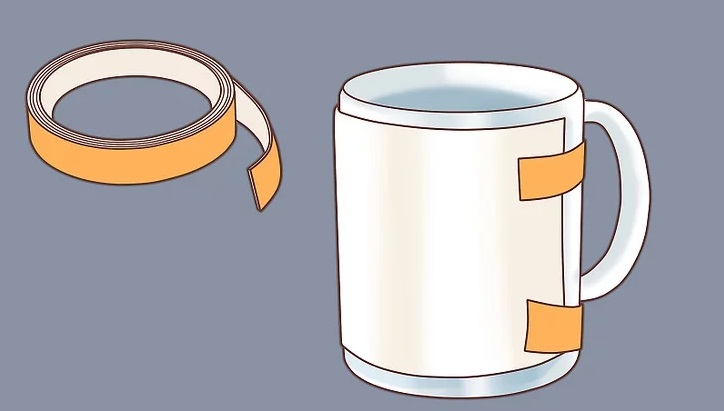

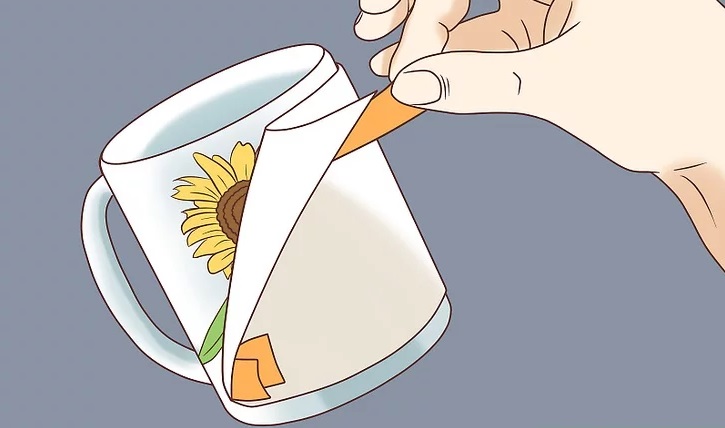

- Wrap it around the sublimation paper into the sublimation coated mug and taped it on with heat tape if it is another material fix the picture in to the material.

- Set the time and temperature.

- Rock – Temperature 180c -8 minutes

- Plate – Temperature 180c – 6 minutes

- Photo glass frame – Temperature 180c – 7 minutes

- Phone covers – Temperature 180c – 9 minutes

- Mugs- Temperature -14 minutes

- Vacuumed it and press the timing and print will start.

- To print the white mug, take out the aluminum board out.

- Lockdown the lid of the machine.

- Once the time is done safely remove the sublimation paper using heat glows (Don’t burn yourself) and check the printed item.

Features of this machine.

- This machine covers all the function of the heat transfer machine

- Sublimation transfer on different sizes and shapes.

- Heat transfer for various type of materials like mug, glass, crystal, metal, and stone

- The machine special high impedance contingent.

- Insulation materials.

- Lightweight and safe

- Streamlined

- resistance heat strips

- Compact internal structure

- Simple yet stylish appearance

- Internal feature 180c clamshell design, easy operations, and space-saving

- Plump dots surface design

- Die-cast aluminum alloy heating.

- Silicon Rubber to vacuum purpose.

- Far infrared radiation coating

- Software and hardware dual temperature control design

- Has an activated carbon air filter to ensure health and safety while operating.

- User friendly.

- 12 mugs at a time great for mass production

- Easy to set time and temperature

In detail about the Machine

| Price | 139,000/= |

| Quality of the output | High Quality |

| Power | 2900 volts |

| Advantages | · Multifunctioning machine

· No need to go for the other machines. · Budget friendly. · 3D Facility. · User Friendly. · Easy to carry. · Excellent quality of the output. · 12 mugs at a time |

| Disadvantages | · Unable to print fabric material.

· It takes the same amount of current to pint a mug and at the same time to print 12 mugs. · 3 Phase power circuit need for this machine and will not compromise with single-phase circuit. |

| Package | Guide Book, Power Code, 2 mug clamps , 1 Bottle clamps, Air horse, 4 Sample materials and the machine. |

| Company Support | · One-year warranty period.

· Training session. · Quickly identify the technical issue and do the needful. · Best budget friendly price ranges. |

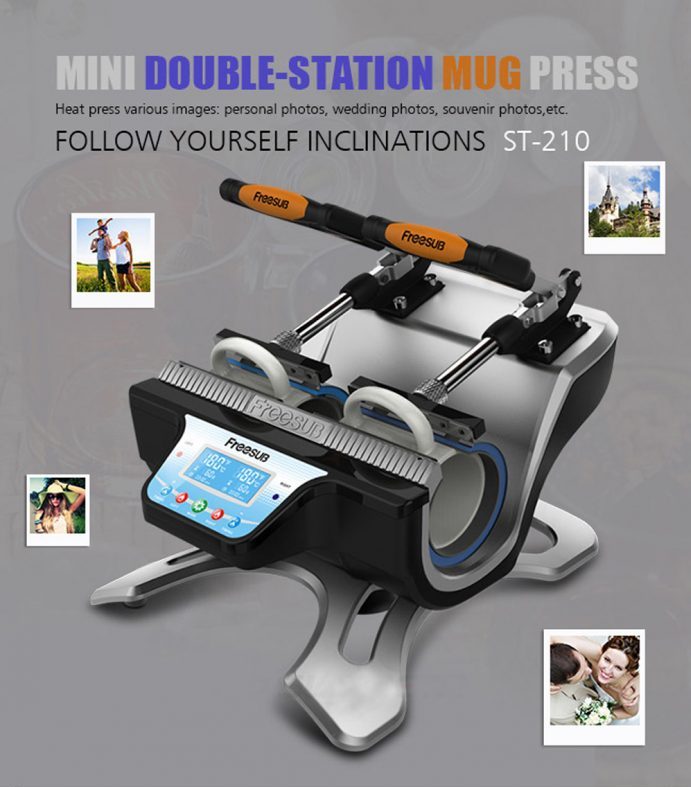

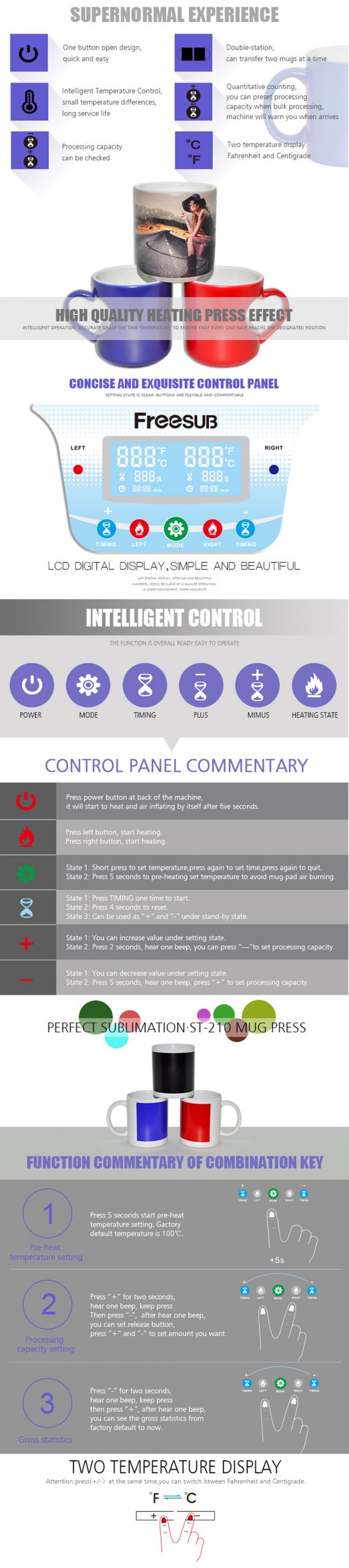

Sublimation Double Mug Press Machine Review

Ideal for long and high-volume production runs, the highly efficient ST-210 Mug Heat Press unit offers the ability to heat two mugs at once. Smooth production is backed by the two individually programmed elements, so you can heat two objects with different settings at the same time

Advantage of the New Machine:

-

Double-station control circuit board

-

Intelligent Temperature Control, small temperature differences, long service life.

-

two temperature displays: Fahrenheit and Centigrade.

-

processing capacity can be checked.

-

Quantitative counting, you can preset processing capacity when bulk processing, the machine will warn you when arrives.

-

the machine comes with a temperature correcting function, that makes the temperature on the screen the same as real temperature.

-

Double-station can transfer two mugs at a time.

Step by step guide to print the mug:

-

Design the artwork on your PC.

-

Print out the image or text to the sublimation paper.

-

Cut out the specific image.

-

Wrap it around the sublimation paper into the sublimation coated mug and taped it on with heat tape.

-

Put the mug in the middle of the clamp.

-

Lockdown the lid of the machine.

-

Set the time as 100 seconds and temperature 180C

-

Once you put the mug the temperature will cool down but, normally, the temperature will cool down for a moment after putting your mugs and eventually will start heating up again.

-

Once the time is done safely remove the sublimation paper using heat glows (Don’t burn yourself) and put the mug into the water-filled container.

-

After 5 minutes your mug is ready to use.

Fiber Laser Machines in Sri Lanka

Fiber Laser Machine in Sri Lanka

The fiber laser cutter is a laser metal cutting system which is capable of metal cutting up to 10 times faster than conventional CO2 systems. It also saves up to 90% of the operational cost compared to any other metal cutting system. This system is High quality, high speed, and high in precision, high efficiency, and dedicated than CO2. The fiber laser cutter is also known as a fiber laser f metal cutting machine, fiber laser cutting machine, fiber laser cutting system, fiber laser cutting equipment, and metal cutting machines.

Lifetime up to 100,000 working hours, and it is suitable for all kinds of metal cutting which will be your good metal working partner.

Softnet offer fiber laser E (economic) model and H (Heavy-duty) Model cutting machines with a power range from 1000-12000W, capable of cutting metal sheets/plates and metal tubes/pipes of stainless steel, carbon steel, galvanized steel, aluminum zinc plate, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials with 0.1 to 30mm thicknesses. The laser generators and cutting heads are world-class brands, such as Ray tools (Switzerland-made) cutting heads. High accuracy SHIMPO speed reducer, is from Japan and Taiwan made HIWIN, and also Japan made SMC pneumatic N2 control. We offer the World’s top brands of laser source IPG and MAX and RAYCUS. And we also offer economical solutions.

The specialty of Softnet is maintaining a large number of spare parts stocks, which will enable us to replace any kind of spare part with no time at all. Keeping the downtime of these machines minimal. We offer a complete two years warranty and our skilled technicians provide island-wide service making us an exclusive Fiber Laser service provider which is unmatchable by anyone else in the industry.

Whatsapp / Viber 0777907779

කොහොමද Mug Print කරගන්නේ !

SoftnetSoftnet කියන්නේ ලංකාවේ අංක 1 සහ ලොකුම sublimation company ඉතින් ඕගොල්ලන්ට පුළුවන් mug machine එකේ ඉඳලා Heat press machines,3D vacuum machine, Laminating Machine, Paper cutting machine, Laser machines, CNC machine, Photo binding machines වගේ ඕනම machine එකක් එකම වහලක් යටින් ලබාගන්න. අපි මේ blog එකේ කියන්න බලාපොරොත්තු වෙන්නේ කොහොමද mug එකක් print කරන්නේ කියලා.අලුතෙන් ව්යාපාරයක් පටන් ගන්න කෙනෙක් එහෙමත් නැත්නම් නිවසේ ඉඳල ව්යාපාරයක් කිරීමට බලාපොරොත්තු වෙන කෙනෙක්ට පටන් ගන්න පුලුවන් පුළුවන් හොඳ ව්යාපාරයක් තමයි Mug printing කියන්නේ. කොහොමද Mug Print කරගන්නේ !Mug එකක් print කරගන්න නම් අපිට අවශ්යය වෙනවා Mug press machine එකක් Sublimation printer, Heat Tapes ඊට අමතරව Sublimation papers.ඉතින් මේ ඔක්කොම දේවල් ඔබට ගන්න පුළුවන් ඉතාම සුළු මුදලකට .Softnet අප ආයතනයේ Mug press machines විශාල ප්රමාණයක් ඇති අතර අප විසින් ඔබේ අවශ්යතාවය අනුව මිලදි ගන්න පුළුවන්. තවද Mug machine එකකට අවුරුද්දක වගකීම් කාලයක් ද අප විසින් ලබා දෙනවා.

පියවර 1 ඔබ තෝරා ගන්නා Sublimation mug එක(11oz) print කිරීමට අදාල වන design එක සකසා ගත යුතුය .මෙහිදී 20cm දිගට සහ උස 8.5cm layout එක ගත යුතුය .Print එක ලබා ගැනීමට පෙර print setting හරහා එය mirror කිරීමටත් print එක high quality කිරිමටත් අමතක නොකල යුතුය.තවද print කිරීමට යොදාගන්නා Mug එක, Paper එක සහ ink, sublimation විය යුතුය.

පියවර 2 ලබාගත් printout එක මඳ වේලාවක් වේලෙන්නට හැර design එක Heat tape කැබැල්ලක් යොදා Mug එකේ ඇලවීම කළ යුතුය.

පියවර 3 ඉන්පසු mug press machine එකේ උෂ්ණත්වය,mug machine එකේ hand press level එක සහ වේලාවක් සකසාගත යුතුය.මෙහිදී ඔබ මිලදීගත් mug machine එකේ මාදිලිය අනුව උෂ්ණත්වය සහ කාලය වෙනස් වේ. පියවර 4 දැන් ඔබට තිබෙන්නේ mug එක machine එක තුළට දමා print කර ගැනීමයි.මෙහිදී නියමිත වේලාව අවසන් වූ ක්ෂණිකයෙන් mug එක clamp එකෙන් ඉවතට ගෙන වතුර භාජනයකට දැමිය යුතුය.එසේ සිදු කරනු ලබන්නේ mug print එකට හානියක් නොවීම සඳහායි.

දැන් ඔබට ඔබගේ අපූරු mug print එක දැක බලා ගත හැක. Softnet අප ආයතන ආයතන සතුව sublimation blank mugs range විවිද වර්ගවලින් ඇති අතර ඔබගේ නිර්මාණයට සුදුසු mug eka තොරගත හැක. තවද අප ආයතනයෙන් ඊට අදාල තාක්ෂණික දැනුම ඔබට නොමිලේ ලබා දෙන අතර අවශ්ය අමතර කොටස් ද ඕනෑ තරම් අප ආයතනයෙන් මිලදී ගත හැකි වීම සුවිශේෂියි. ඔබට sublimation අදාල ගැටළු තිබේ නම් අපිට comment කරන්න අමතක කරන්න එපා. |